A Breakthrough in MicroNeedle Technology

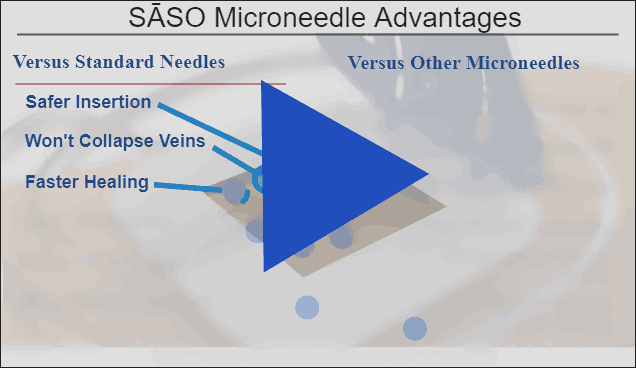

Proprietary SĀSO™ (Self-Assembled Sealed-Origami) technology is the first and only practical microneedle technology for IV use, revolutionary in its transformational potential. SĀSO™ processes produce microneedle arrays in one simple mask step (compared to 3-5 complicated interdependent steps), yielding much longer needles than any other technology at much lower cost, and providing a level of unequaled robustness and strength.

What Is a SĀSO™ Microneedle Array?

Microneedle arrays are comprised of hundreds of hollow needles each as big as a human hair. Until now they were useful only for injecting substances only as deep as a millimeter. SĀSO™ processing has changed that with low-cost robust microneedles of varying length, long enough to access very deep tissues, vastly expanding the viable market.

SĀSO Microneedle Array Insertion

Stabilizes the vein and controls the insertion

Protects microneedles before insertion

Self-lighting to view progress

Base supports and protects the microneedle assembly

Shims (not shown) keep needle ends in vein center

SĀSO™: Self-Assembly Sealed-Origami

How They’re Made:

- 3 MEMS Steps: Cut, Curl, Seal

- Only 1 photomask step

- Minimal material removal (excellent tool utilization)

- Tolerates high tool variability

- Significant reduction in cost